Cleanroom accessories

Home / Cleanroom accessories

Equipment for metalfree workplaces

Quick Dump Rinse

(QDR)-Basin

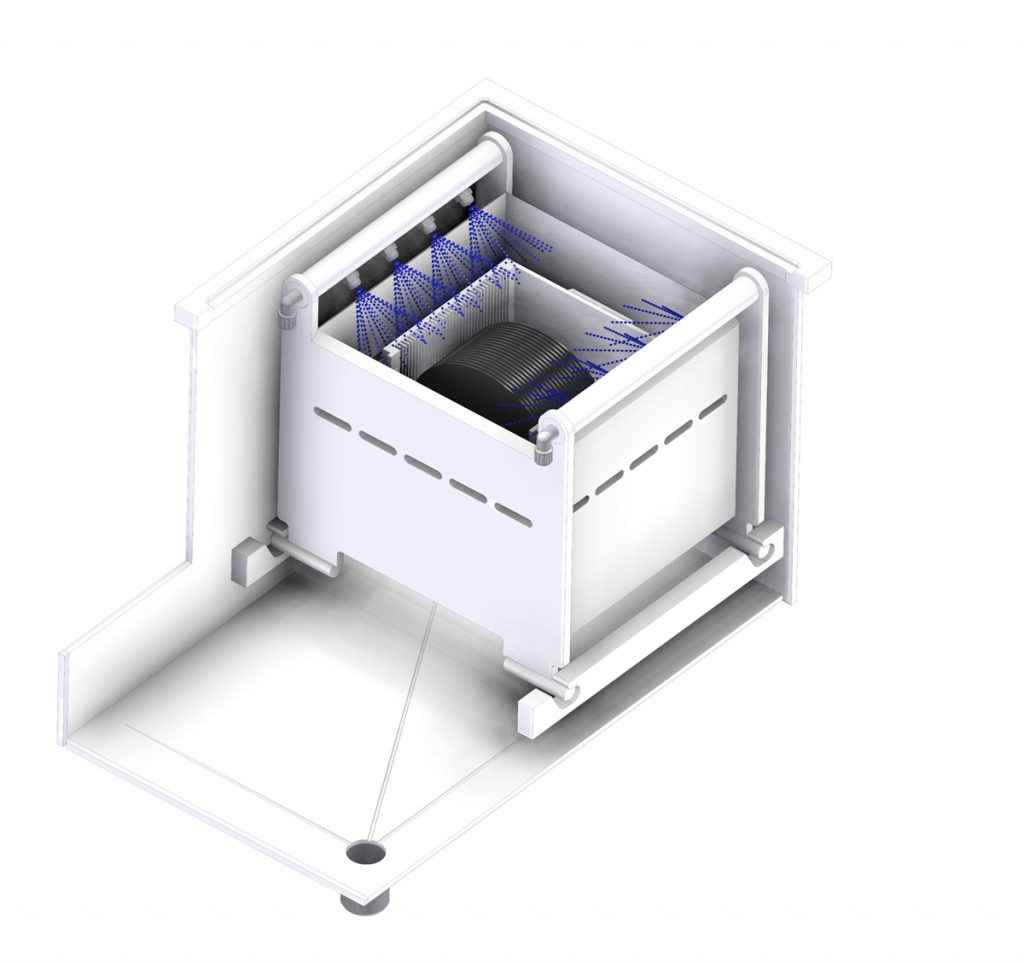

Quick Dump Rinse (QDR) basin

After the chemical treatment of semiconductor wafers for cleaning, etching or stripping applications, it is important to rinse all components properly to avoid chemical residues. Once removed from the chemical bath, the semiconductor plate surface is still covered with chemicals that cause a continuous chemical process outside the bath. This chemical process can lead to over-etching or detachment, resulting in production downtime.

To avoid these problems, it is necessary to rinse the semiconductor wafers properly with Dl water using a quick dump rinse or a quench.

The Quick Dump Rinse (QDR) basin has a modular design. It is therefore possible to disassemble the QDR tank into two separate components and remove them from the system. Additional comfort is provided by the spray and drain system, which is designed to be removed, cleaned or replaced together with the process tank.

Show Quick Dump Rinse (QDR) basin DatasheetMetalfree furniture

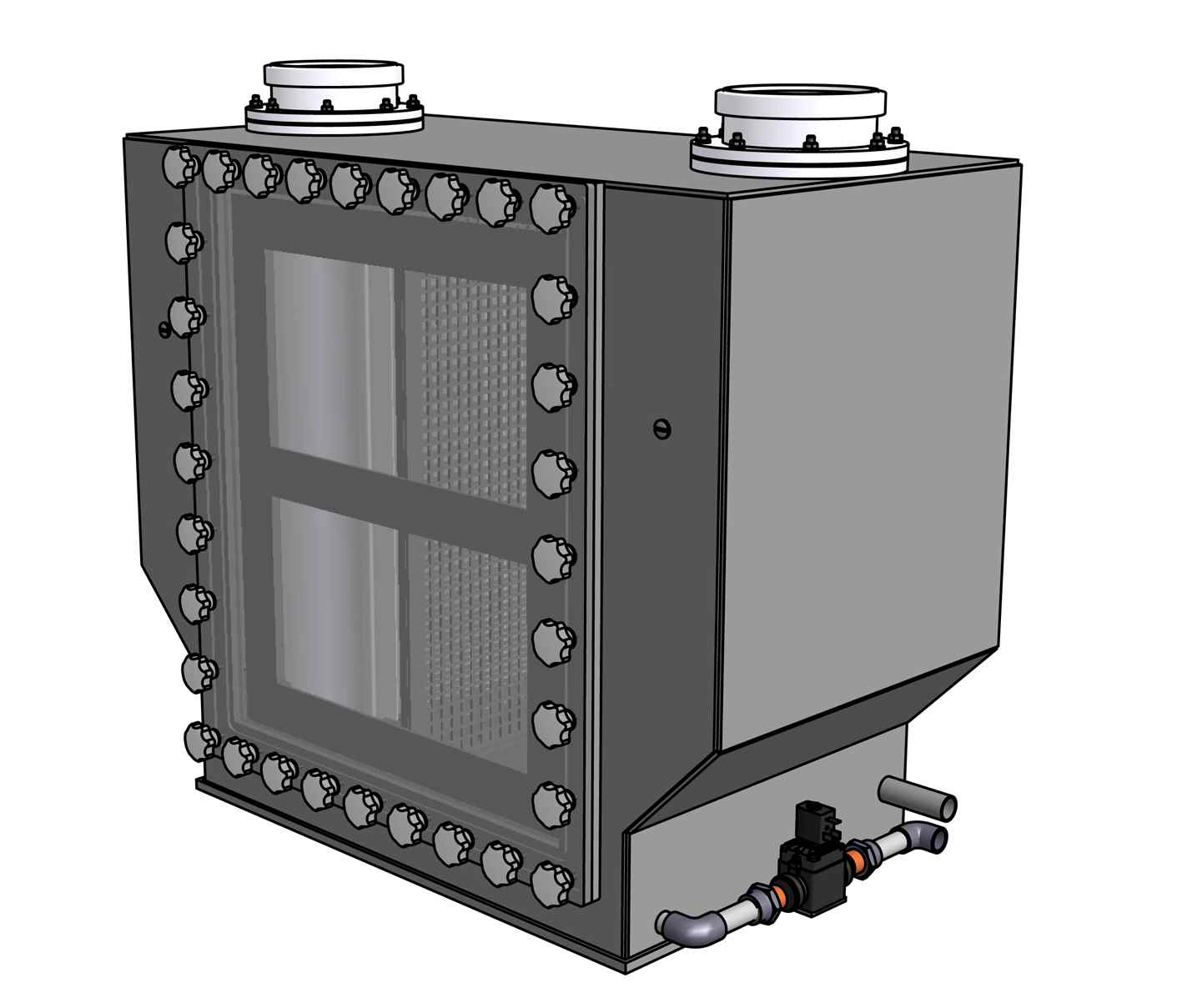

Exhaust air scrubber

- Spray absorption system for the cleaning of smoke and process

gases - Compact design

- Completely manufactured from modern thermoplastics

- Horizontal airflow

- High humidification performance with optimal flowrate current

- Prevention of washing liquid outlet by droplet separator and filters

- Water is used as washing liquid

- High operating safety

- Calibrated to operate with our metalfree workstations

- Individual control settings

Ultrasonic cleaning device

- Oscillating tank: Interior dimensions Dia 214 mm, 103 mm high

- Degree of protection: IP 64

- Time switch: 1 – 15 min and ∞ adjusted by software

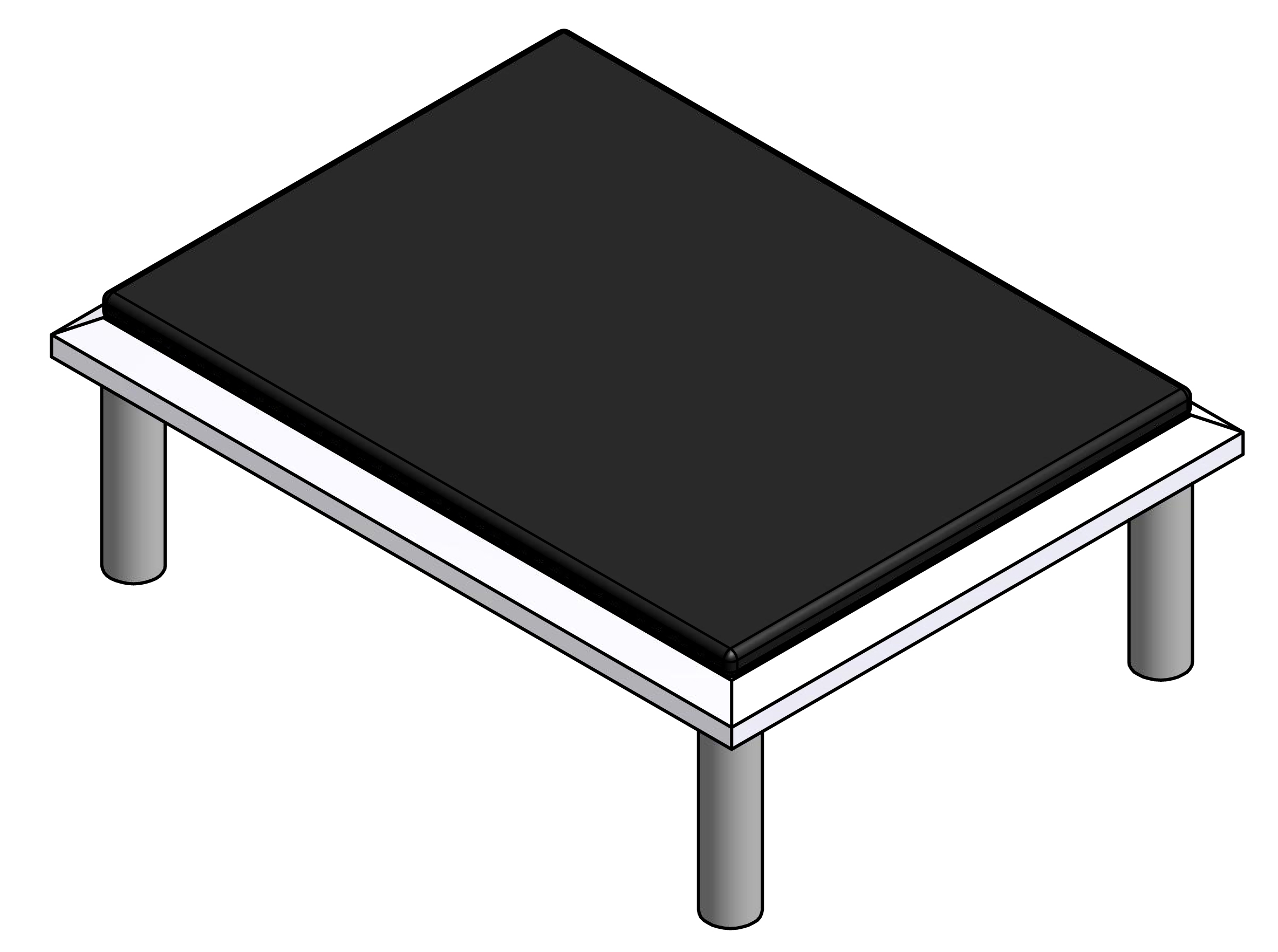

Hot Plates

- Totally coated with PTFE

- Complete coated connection line

- 20 years tested of coating in toughest environmental conditions

and applications - Low weight

- Special consistent heat distribution

- Very fast warming on low energy consumption

- Save long-term operation by two separate safety devices

- IP67 protected connection plug for simple connection in

application room

Thermal digestion unit (TAE)

- Specifically designed for applications in ultra-trace analysis for

thermal digestion of samples - Totally coated with PTFE

- Complete coated connection line

- 20 years tested of coating in toughest environmental conditions

and applications - Lightweight

- Special consistent heat distribution

- Very fast warming on low energy consumption

- Preprogrammed control for individual sample processing

- Save long-term operation by two separate safety devices

- IP67 protected connection plug for simple connection in

application room